ACI method of concrete mix design is based on the estimated weight of

the concrete per unit volume. This method takes into consideration the

requirements for consistency, workability, strength and durability.

(a) Depending on the degree of workability and placing condition determine the slump value.

(b) Depending on the economical availability and dimensions of the structure determine the maximum size of aggregate.

(c) For the given slump and maximum size of coarse aggregate determine the amount of mixing water.

(d) Determine the minimum water-cement ratio either from strength considerations or from durability considerations.

(e) Determine the amount of cement per unit volume of concrete from steps (c) and (d). This cement content should not be less than the cement content required based on durability criteria.

(f) Determine the amount of coarse aggregate required for a unit volume of concrete. This value is multiplied by the dry rodded unit weight of the aggregate to get the required dry weight.

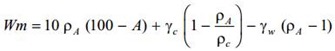

(g) Determine the amount of fine aggregate. If the weight of concrete per unit volume is assumed, the required weight of fine aggregate is obtained by the difference between the weight of fresh concrete and the total weight of all other ingredients. The weight of fresh concrete may be estimated by using following equation:

Where,

= weight of fresh concrete in kg/m3

= weight of fresh concrete in kg/m3

= weighted average specific gravity of combined fine and coarse sand,

= weighted average specific gravity of combined fine and coarse sand,

= specific gravity of cement = 3.15

= specific gravity of cement = 3.15

= cement requirement in kg/m3

= cement requirement in kg/m3

= mixing water requirement in kg/m3

= mixing water requirement in kg/m3

A = Air content in percent.

(h) Adjust the mixing water quantity on the moisture content in the aggregate.

(i) Check the calculated mix proportions by trial batches prepared and tested in accordance with the IS specifications and make another trial if required.

Following are the steps of ACI Method of Concrete Mix Design:

(a) Depending on the degree of workability and placing condition determine the slump value.

(b) Depending on the economical availability and dimensions of the structure determine the maximum size of aggregate.

(d) Determine the minimum water-cement ratio either from strength considerations or from durability considerations.

(e) Determine the amount of cement per unit volume of concrete from steps (c) and (d). This cement content should not be less than the cement content required based on durability criteria.

(f) Determine the amount of coarse aggregate required for a unit volume of concrete. This value is multiplied by the dry rodded unit weight of the aggregate to get the required dry weight.

(g) Determine the amount of fine aggregate. If the weight of concrete per unit volume is assumed, the required weight of fine aggregate is obtained by the difference between the weight of fresh concrete and the total weight of all other ingredients. The weight of fresh concrete may be estimated by using following equation:

Where,

A = Air content in percent.

(h) Adjust the mixing water quantity on the moisture content in the aggregate.

(i) Check the calculated mix proportions by trial batches prepared and tested in accordance with the IS specifications and make another trial if required.

No comments:

Post a Comment